How To Properly Align and Tension Rubber Tracks

Feb 20th 2025

Feb 20th 2025

The alignment and tension of rubber tracks are essential for keeping your equipment running smoothly. Whether you are a maintenance technician or a new equipment operator, understanding how to align and tension rubber tracks properly can save time, reduce costs, and extend the lifespan of your machinery. This guide will walk you through the essential steps and techniques to help you get your rubber tracks back in working order.

By the end of this guide, you’ll know how to identify misalignment issues, adjust track tension, and follow best practices for ongoing maintenance.

Rubber tracks are critical components of heavy machinery, such as excavators, skid steers, and track loaders. They provide the necessary traction to operate equipment in a variety of environments, such as muddy construction sites and rugged off-road terrains. Rubber tracks distribute the weight of the machine more evenly than wheels and tires, reducing ground pressure and improving stability.

When rubber tracks are misaligned or insufficiently tensioned, several problems can arise:

Regular maintenance is vital to avoid rubber track issues. The first step toward prevention is understanding the signs of misalignment and poor tension.

Catching alignment and tension issues before they cause further damage can save you from expensive repairs. Here are some signs to watch for:

Use a temperature gun to measure the temperature of both sides of the lugs. A difference of 20 degrees or more suggests that there’s more friction on one side of the track than the other.

If the rubber track sags excessively when you look at it from the side, it’s too loose. Insufficient tension can cause the track to derail or slip off of the undercarriage during operation, which is a serious safety hazard. Tracks with no gap between the rollers and the track body are likely too tight and putting stress on both the tracks and driving components.

Finally, loose tracks can slip under the weight of a load, particularly in wet conditions. Identifying these issues allows you to address problems before they worsen.

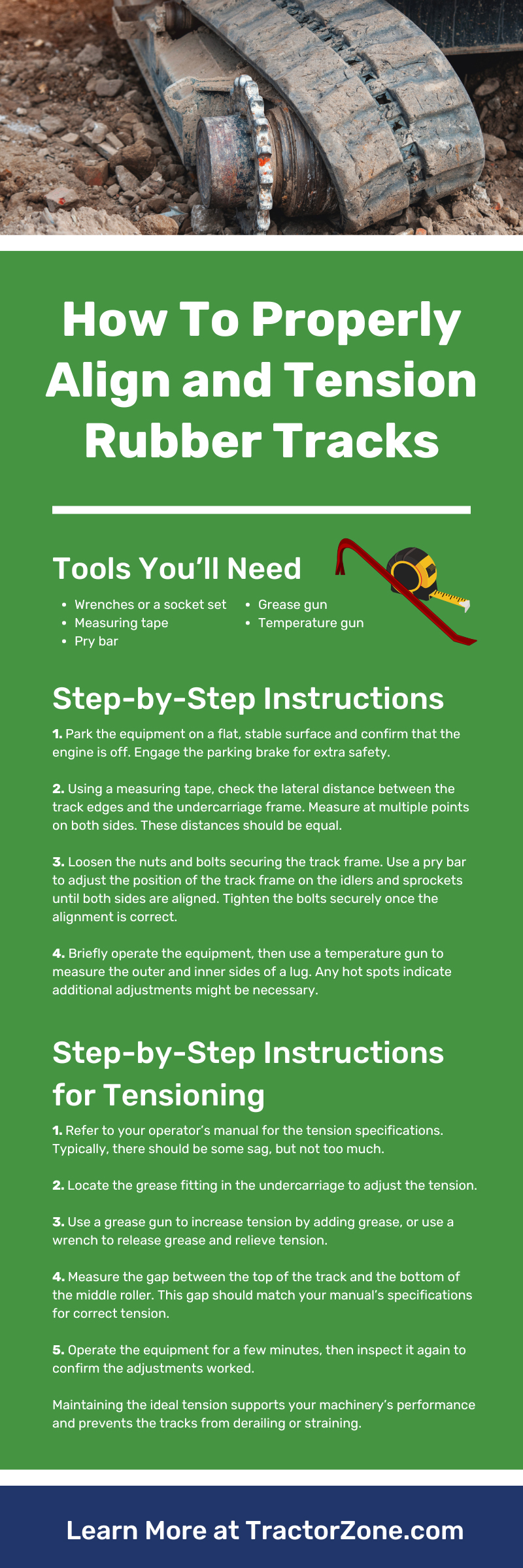

Correcting misaligned rubber tracks is easy if you follow these step-by-step instructions:

The next steps in maintaining rubber tracks are checking and adjusting the tension. Follow these steps to get it right:

Confirm that the equipment is off, with the parking brake engaged. Also, wear protective gloves and goggles to avoid injuries.

Maintaining the ideal tension supports your machinery’s performance and prevents the tracks from derailing or straining.

Investing a little time in routine maintenance can extend the lifespan of your equipment’s rubber tracks. By following these best practices, you can prevent issues before they start and keep your equipment running reliably.

Aligning and tensioning rubber tracks extends the life of your equipment and makes it safer for operators. By understanding how to align and tension rubber tracks properly, you can avoid downtime and ensure top performance every time you use your machinery.

Don’t overlook the importance of high-quality tracks. Investing in durable, heavy equipment rubber tracks and staying on top of maintenance keeps your machinery operating at its best.