How To Properly Store Your Heavy Equipment

Dec 30th 2024

Dec 30th 2024

Storing heavy equipment might not be the first task that comes to mind after completing a demanding project or ending a long workday. However, understanding how to properly store your heavy equipment is essential for keeping it in top-notch condition, extending its lifespan, and saving money on future repair costs. Whether you're wrapping up a busy construction season or need to temporarily park your machinery, using the right storage techniques will protect your equipment and ensure it’s ready to perform when you need it most.

This guide will cover everything from understanding your equipment’s specific needs to choosing the right storage space. By the end of this blog, you’ll know how to handle the storage process with ease.

Heavy equipment comes in a variety of forms, each with unique storage requirements. Skid steers, excavators, bulldozers, cranes, and loaders face wear and tear from environmental factors, and improper storage can accelerate that damage.

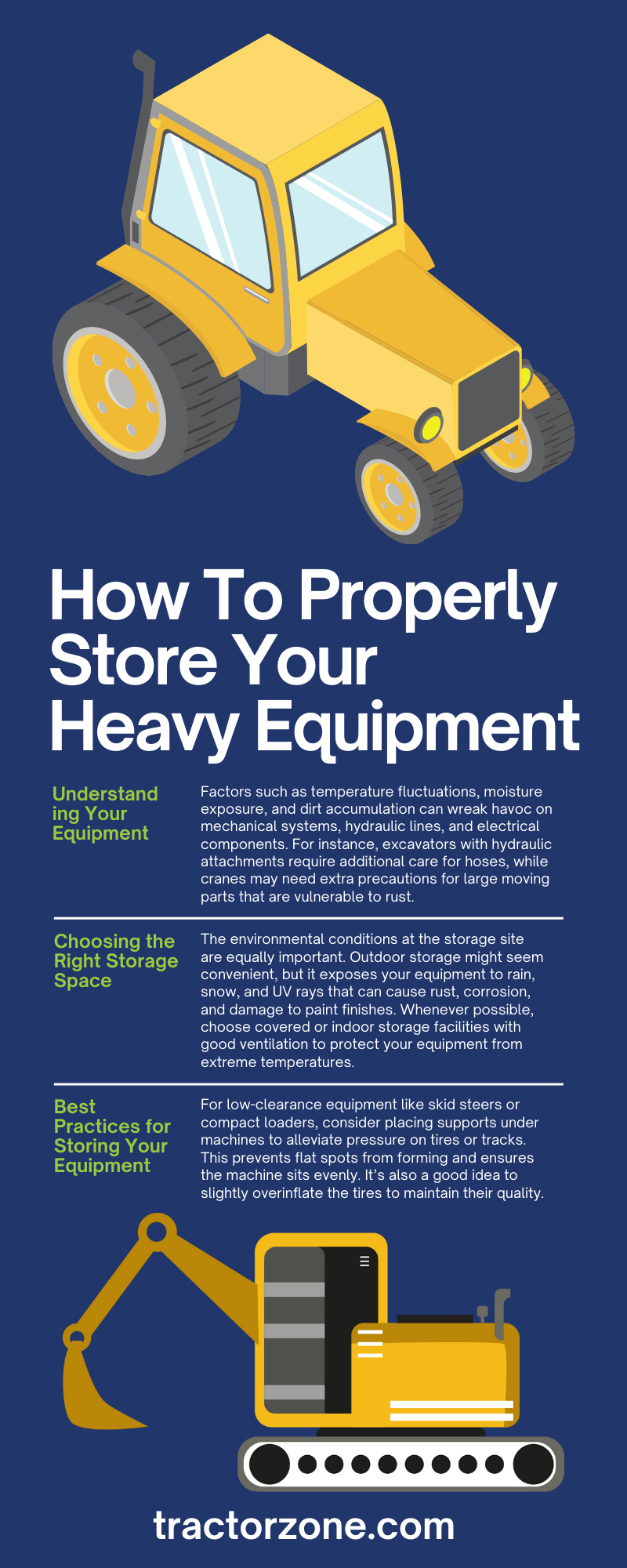

Factors such as temperature fluctuations, moisture exposure, and dirt accumulation can wreak havoc on mechanical systems, hydraulic lines, and electrical components. For instance, excavators with hydraulic attachments require additional care for hoses, while cranes may need extra precautions for large moving parts that are vulnerable to rust.

The biggest variable to consider is how long the equipment will remain in storage. Short-term storage has different requirements than long-term storage. The longer your equipment remains out of service, the more preparation it will require. Proper storage is vital for avoiding issues like internal rust, fuel degradation, or flat tires.

By understanding the specific needs of each machine, you’ll be able to create an environment that reduces risk and preserves function.

A critical step in keeping your heavy equipment in great condition during idle periods is selecting an appropriate storage location. Your choice of space matters—it can safeguard equipment against theft, protect it from harsh elements, and allow you to easily access the machinery when it’s time for work to resume.

Opting for a secure location is essential. Construction equipment is very valuable, which makes it a target for theft. Fenced yards with surveillance systems or enclosed buildings provide the added security your investments deserve.

The environmental conditions at the storage site are equally important. Outdoor storage might seem convenient, but it exposes your equipment to rain, snow, and UV rays that can cause rust, corrosion, and damage to paint finishes. Whenever possible, choose covered or indoor storage facilities with good ventilation to protect your equipment from extreme temperatures.

Lastly, ensure the storage area has sufficient space for easy maneuverability and organization. The last thing you want is to overload a cramped warehouse or yard, risking accidental damage while moving machinery in or out of storage.

Storing heavy equipment involves more than just parking it and walking away. A few key steps can make a significant difference in how well your machines hold up during downtime. This preparation process is straightforward and ensures everything is in optimal condition when it’s time to get back to work.

Start by giving your equipment a thorough cleaning. Dirt, grease, and residue can trap moisture, leading to rust or corrosion over time. Use a high-power pressure washer to remove grime from hard-to-reach corners, paying particular attention to joints, moving parts, and the undercarriage. Once cleaned, allow the machinery to dry completely to prevent lingering moisture from causing rust or corrosion. Cleaning isn’t just about aesthetics—it’s about protecting critical machine components.

Proper lubrication is a crucial step in preventing wear during storage. Follow the manufacturer’s guidelines or the directions from your heavy equipment parts supplier. Most heavy equipment needs lubrication on all the moving parts, including hinges, joints, and hydraulic lines. Not only does this keep the components in working order, but it also creates a protective barrier against moisture and rust. Be generous yet precise with lubrication—an even coating ensures comprehensive coverage.

Address any outstanding maintenance tasks before storage. Replace worn-out filters, top off fluids like engine oil and coolant, and inspect belts and hoses for cracks. Small issues left unattended can escalate while machinery sits idle, turning what should have been routine maintenance into major repairs. A little effort up front will save you a headache later.

Leaving fuel sitting idle for extended periods can lead to degradation and clogs. If equipment needs to remain in storage for an extended period, add a fuel stabilizer to the tank before filling it completely. Running the engine for a few minutes afterward circulates the stabilizer throughout the system, preventing damage to fuel lines and injectors.

Storage preparations don’t stop once everything is cleaned, lubricated, and maintained. Following a few best practices can help keep your equipment in optimal condition during its downtime.

For starters, arrange your machinery in a logical, organized fashion. Placing tools and smaller equipment around heavier machines can lead to frustration or damage when it’s time to retrieve them. Use shelving or storage bins to organize smaller components or tools.

Another important habit is keeping a detailed inventory of all stored equipment. Include dates of maintenance, expected storage duration, and any parts that may need inspection during that time. An organized system makes it easier to stay on top of regular checks.

For low-clearance equipment like skid steers or compact loaders, consider placing supports under machines to alleviate pressure on tires or tracks. This prevents flat spots from forming and ensures the machine sits evenly. It’s also a good idea to slightly overinflate the tires to maintain their quality.

Even when your equipment is in storage, it shouldn’t be off your radar. Scheduling regular maintenance checks is an essential task even during the off-season.

Inspect the machinery for any signs of damage, such as leaks, rust, or loose fittings. Rotate tires every few weeks to maintain even pressure and prevent flat spots. Start engines periodically to ensure things aren’t seizing up, and test pumps or hydraulics when applicable.

Regular inspections are particularly important if your equipment will re-enter a job site during a different season, as temperature changes can affect component performance. These efforts preserve the usability and value of your machinery, keeping it ready for seamless operations when needed.

Knowing how to properly store your heavy equipment goes a long way toward protecting your investment. From understanding the unique needs of various machinery to carefully choosing secure storage spaces and planning preparation steps, every action contributes to extending the life and performance of your equipment.

Whether you’re preparing for a short break or a long off-season, these tips will help keep your machinery in great shape. Take proactive steps today by implementing these best practices, ensuring your heavy equipment is ready to rise to the occasion when the time comes. Proper storage doesn’t just safeguard your equipment; it saves you valuable time and money in the long run.