Comparing Mechanical and Hydrostatic Transmissions

Aug 15th 2025

Aug 15th 2025

Heavy equipment operators must frequently make decisions that affect productivity, fuel costs, and maintenance schedules. One of the most important choices involves selecting the right transmission system for your machinery. Two dominant technologies compete for your attention: mechanical and hydrostatic transmissions. Each system offers distinct advantages, but understanding their differences and choosing the right one can potentially save you thousands of dollars and countless hours of downtime.

Modern construction and mining equipment demand more from transmission systems than ever before. Operators need precise control, fuel efficiency, and reliability across diverse working conditions. The transmission you choose affects everything from operator comfort to long-term maintenance costs.

Mechanical transmissions use physical gears to transfer power from the engine to the wheels or tracks. These systems rely on clutches, torque converters, and gear sets to provide different speed and torque combinations. The operator selects gears manually or through automated controls, engaging specific gear ratios to match operating conditions.

The design centers around mechanical linkages and hydraulic clutches that physically connect and disconnect power flow paths. When you shift gears, the transmission disengages one gear set and engages another, creating a new ratio between input and output speeds. This direct mechanical connection provides efficient power transfer with minimal energy loss.

Most modern mechanical transmissions feature multiple forward gears and reverse options. Advanced versions include powershift capabilities that allow operators to change gears without stopping or using a clutch pedal. These systems often incorporate electronic controls that optimize shift points based on load conditions and operator preferences.

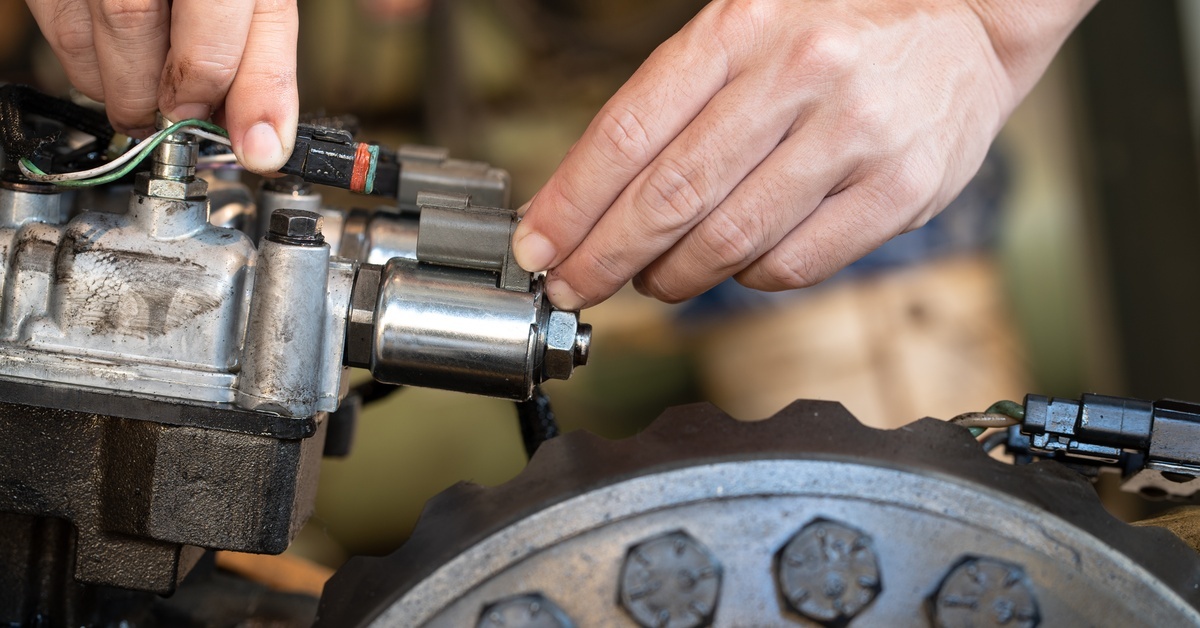

Hydrostatic transmissions eliminate traditional gears, using hydraulic pumps and motors to transfer power. The engine drives a variable-displacement hydraulic pump that sends pressurized fluid to hydraulic motors connected to the drive wheels or tracks. Speed and direction control happen by varying the pump output and motor displacement.

This fluid power system offers variable speed control within its operating range. Operators can achieve any speed from zero to maximum without discrete gear steps. The hydraulic components provide smooth acceleration and deceleration, making these systems popular for applications requiring precise maneuvering.

The hydrostatic design allows independent control of each drive motor in tracked vehicles, enabling zero-radius turns and exceptional maneuverability. Electronic controls manage pump displacement and motor operation, often integrating with other machine functions for optimized performance.

Comparing mechanical and hydrostatic transmissions reveals important differences in operational characteristics. Mechanical systems typically deliver higher overall performance, especially at maximum speed and load conditions. The direct mechanical connection minimizes energy losses, translating to better fuel economy during high-speed transport and heavy pulling applications.

Hydrostatic systems excel in low-speed, high-torque situations where precise control matters more than peak efficiency. These transmissions provide excellent modulation for delicate operations such as finish grading or material placement. The infinitely variable speed control eliminates the need for constant gear changes in varying conditions.

Power delivery characteristics differ substantially between systems. Mechanical transmissions provide peak power efficiency at specific RPM ranges corresponding to optimal gear ratios. Hydrostatic systems maintain consistent power availability across their entire speed range but with lower peak efficiency due to hydraulic losses.

Mechanical transmissions dominate applications requiring high-speed operation and maximum fuel efficiency. Highway-capable equipment and large bulldozers often use mechanical systems for their superior efficiency during transport and heavy draft work. Construction equipment operating in open areas with consistent loads benefits from mechanical transmission efficiency.

Road maintenance equipment, pavers, and large excavators commonly feature mechanical transmissions. These machines spend significant time operating at steady speeds where mechanical efficiency advantages become apparent. The robust design handles high power loads reliably over extended operating periods.

Hydrostatic systems work best in applications demanding precise speed control and frequent direction changes. Compact track loaders, skid steers, and landscaping equipment use hydrostatic drives for their superior maneuverability and operator ease. Urban construction projects benefit from the precise control these systems provide.

Specialty applications such as concrete pumps, street sweepers, and material handlers often specify hydrostatic transmissions. The smooth, variable speed control integrates well with work functions requiring coordinated movement. Equipment operating in confined spaces particularly benefits from hydrostatic transmission capabilities.

Mechanical transmission maintenance focuses on gear oil changes, clutch adjustments, and replacement of worn components. These systems typically require service at longer intervals but involve more complex procedures when major repairs become necessary. Component accessibility affects maintenance costs and downtime duration.

Filter changes, oil analysis, and periodic inspections maintain mechanical transmission performance. Clutch wear monitoring prevents catastrophic failures that could damage expensive internal components. Proper maintenance practices extend service life significantly, making mechanical systems cost-effective over long operating periods.

Hydrostatic systems require frequent hydraulic fluid changes and filter maintenance to prevent damage from contamination. These transmissions are sensitive to fluid cleanliness and operating temperature. Regular fluid analysis helps identify potential problems before they cause expensive component failures.

Heat management is critical in hydrostatic applications. Adequate cooling system maintenance prevents overheating that damages pumps and motors. When sourcing replacement components, operators often find that heavy equipment aftermarket parts from suppliers such as Tractor Zone provide cost-effective alternatives to original equipment manufacturer options without compromising performance or reliability.

Mechanical systems generally cost less upfront but require more expensive maintenance procedures. Major overhauls involve gear replacement, clutch rebuilds, and precision adjustments that demand specialized tools and expertise.

Hydrostatic transmissions command higher initial prices due to their complex hydraulic components and electronic controls. However, routine maintenance procedures are typically simpler and less time-consuming. Component replacement often involves complete pump or motor units rather than internal rebuilds.

Operating costs depend heavily on application requirements. Mechanical transmissions deliver better fuel economy in high-speed, steady-load applications. Hydrostatic systems may consume more fuel but provide productivity advantages in applications requiring precise control and frequent maneuvering.

Application requirements should drive transmission selection decisions. High-speed operations favoring fuel efficiency point toward mechanical transmissions, while applications requiring precise control and maneuverability benefit from hydrostatic systems.

Operator skill levels also affect transmission choice. Mechanical systems may require more training for optimal operation, while hydrostatic controls are often more intuitive for new operators. Consider your workforce capabilities when evaluating options.

Comparing mechanical and hydrostatic transmissions helps you make the best decision for your operational needs. However, technology continues evolving. Electric drive systems are emerging as alternatives for specific applications, while hybrid systems combine multiple technologies for optimized performance.

Mechanical systems continue improving performance and control sophistication, while hydrostatic designs advance in both efficiency and durability. Your choice should align with current needs while considering future requirements.

Transmission selection greatly impacts equipment performance, operating costs, and operator satisfaction. Mechanical systems offer proven performance output for high-speed applications, while hydrostatic drives provide better control for precise operations. Contact Tractor Zone about your specific requirements, operating conditions, and long-term goals, and let us help you make the best choice for your equipment needs.